Creating patches with the all new Draped Curve feature

Cevotec’s Fiber Patch Placement (FPP) process is used to automate the production of complex composites by dividing the laminate into multiple smaller pieces of same or similar shape – so called patches. The positioning of each individual patch can have an influence on the overall performance of the part. Since a laminate can consist of several thousands of patches, a sophisticated tool is needed to assist the designer in the creation of such laminates. Artist Studio is Cevotec’s software solution for designing FPP laminates – featuring unique functionalities to help you create the perfect laminate for your application.

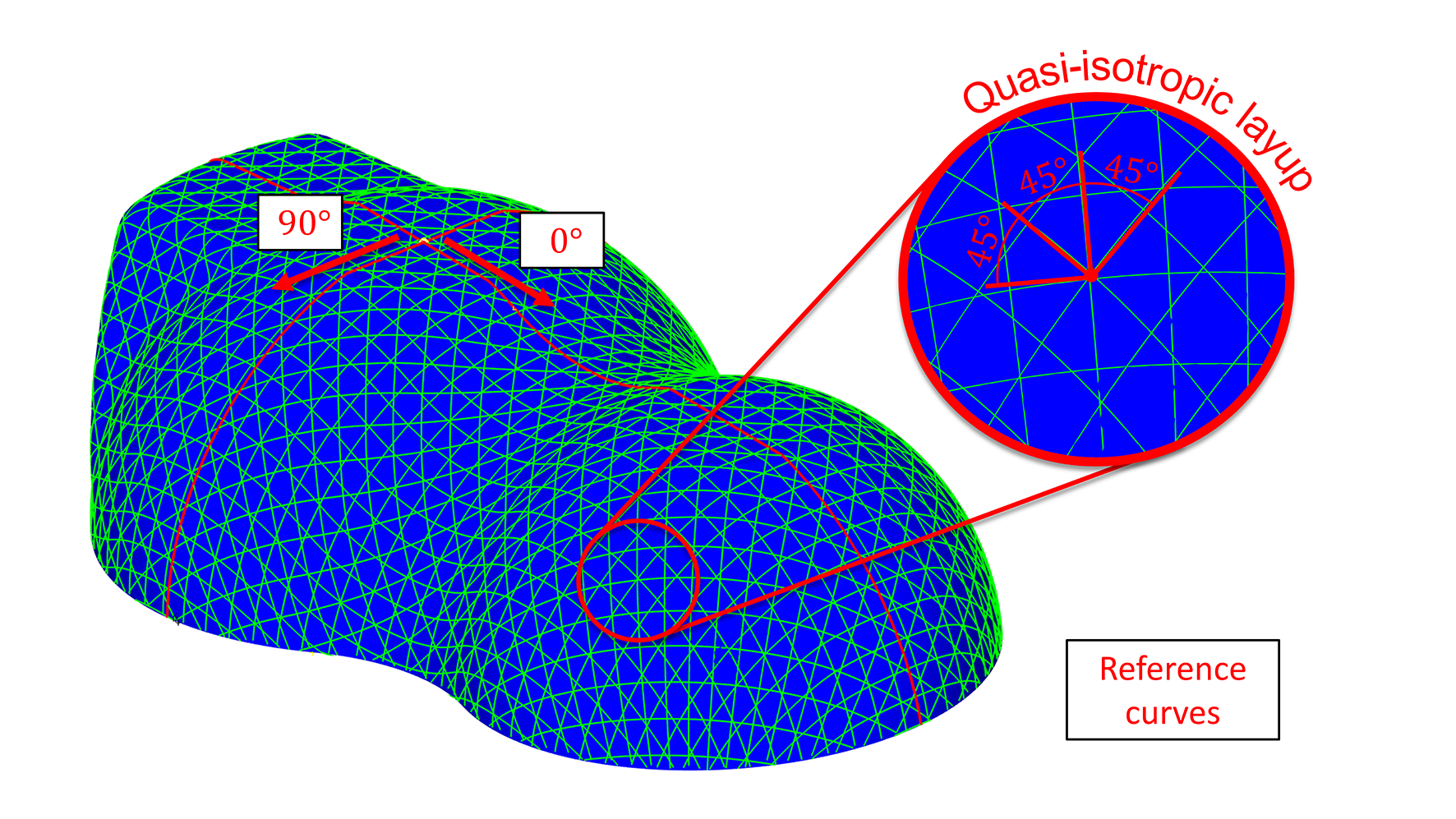

One of Artist Studio’s strengths has always been the creation of custom patch patterns, especially for local reinforcements along curvilinear loadpaths. Now, with the brand-new Draped Curve feature, Artist Studio can also support you with the creation of more traditional laminates like biaxial ([0°, 90°]) or quasi-isotropic (QI, e.g. [0°, 90°, +45°, -45°]). In Artist Studio 1.3 Cevotec introduces the new kinematic draping features, enabling our users to predict the shape of applied patches with even further increased accuracy.

We now use the very same fast and reliable algorithm to bring our patch creation to the next level. It’s possible to create FPP laminates with fiber orientations similar to traditional woven fabrics that feature a 90° angle between warp and weft direction, together with the ability to drape this pattern over complex shapes. But it doesn’t stop here: you can also add additional +/- 45° layers that follow the same principle. So now you’re basically only a few clicks away from a QI laminate for you whole part. And it wouldn’t be FPP if you couldn’t still pick any arbitrarily curved line as your 0° reference – enabling more sophisticated patch patterns than ever before.

The Draped Curve feature is yet another tool that originated from request of our industrial clients working with FPP technology. We constantly strive to understand the needs of our clients and to provide users of Artist Studio with the best experience possible. Arrange a software demonstration with our team to learn more.

About Cevotec:

Munich-based automation specialist Cevotec enables manufacturers to build complex composites in high volume and quality. With Fiber Patch Placement based SAMBA systems, Cevotec offers customized, fully automated fiber layup systems with integrated process control for manufacturing complex 3D geometries and multi-material laminates. ARTIST STUDIO is the technology-specific CAD-CAM software for generating patch-based fiber laminates and automated robot programming. Cost and time reductions of 20-60% can be realized when switching from manual layup to Cevotec’s SAMBA systems. Manufacturers also benefit from a comprehensive service portfolio, including application-specific customizations and FE-based component development.

This artile is published by: